Optimize your yacht manufacturing processes

Whether high-performance sailboats set regatta records, electric sport boats, or custom-built luxury yachts, the guiding principles remain the same: lighter, faster, and stronger.

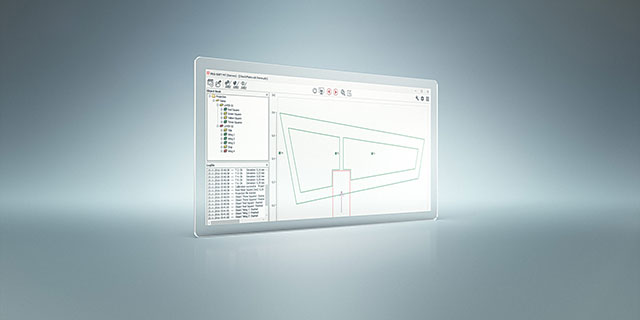

Shipbuilders around the globe rely on LAP's laser projection systems to optimize the performance and quality of their vessels. Our systems deliver unmatched precision and significantly accelerate production processes, particularly in assembly and composite layup.

Being proven in the aerospace and wind energy sectors, LAP’s laser projectors deliver exceptional accuracy in composite layup for hulls and masts using carbon fiber mats, ensuring superior quality and efficiency in every build.

Laser projections ensure the exact alignment and placement of interior components in the deck and hull, ensuring both aesthetic and functional perfection. From cable routing and socket positioning to window recesses, every element is installed swiftly, securely, and with pinpoint accuracy. Stability-critical components, such as bulkheads, are also precisely placed using our laser projectors.