COMPOSITE PRO - acceleration for your production processes in rotor blade manufacturing

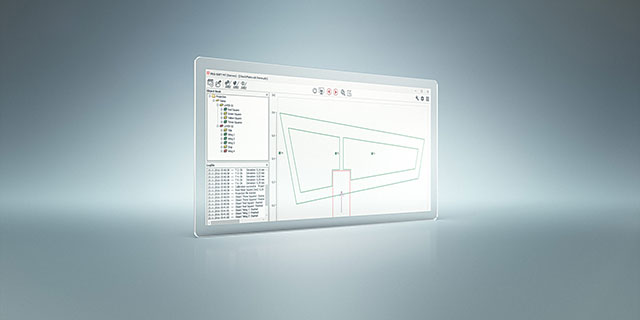

COMPOSITE PRO is a system solution consisting of CAD-PRO laser projectors and our PRO-SOFT software. Together, the projectors and software simplify and accelerate manual composite layup processes. In wind turbine blade production, our industrial laser projectors are used for placing glass fiber reinforced (GFRP) composite plies in the rotor blade half shell with millimeter accuracy.

Using CAD data, laser projectors precisely display the contours onto the mold’s curved surfaces. This allows exact laying of the GFRP-plies along the displayed laser lines. The projectors can also display positions of other molded parts introduced into the blade for reinforcement.

Several projectors with overlapping ranges cover the entire length of the wings. To work faster on large tools, working areas can be divided and assigned to different projectors. Teams working on the same wing can now perform different tasks simultaneously. Our laser projection systems coverall common 3D-shaped blades including pre-styled winglets, and produced lengths of more than 100 meters.