RadCalc QA: ensuring safe and efficient radiotherapy throughout Australia

Cancer care provider GenesisCare is using LAP’s RadCalc platform to perform software-based quality assurance of all its radiotherapy treatment plans

GenesisCare is the largest private radiation oncology provider in Australia, operating across five states and treating around 30,000 cancer patients each year. At the heart of this organization, ensuring the safety and efficiency of all patient radiotherapy treatments lies a single server running LAP’s RadCalc quality assurance (QA) software.

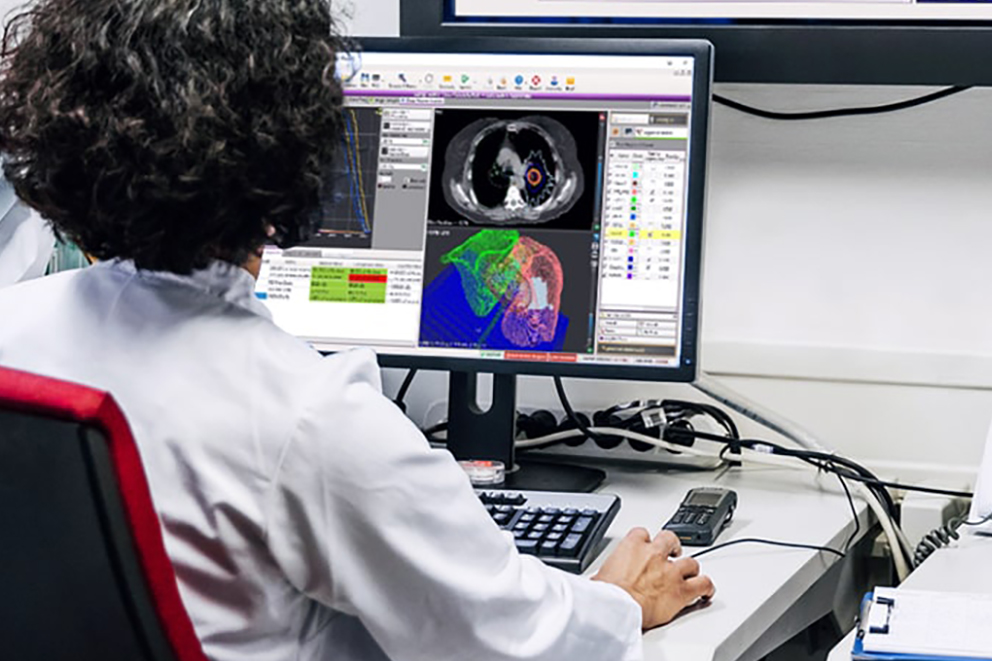

RadCalc is a 100% software-based platform designed to streamline daily patient QA. The latest release, version 7.3.2, incorporates advanced 3D algorithms for secondary verification of radiotherapy plans, EPID-based pre-treatment QA and in vivo dosimetry, as well as automated 3D calculation based on treatment log files.

For GenesisCare, RadCalc provides independent secondary verification for 100 to 130 new plans each day, from more than 43 radiation oncology facilities across the country. The use of a single QA platform for all satellite centres helps to ensure that every patient receives the same high standard of care. “With everyone using the same software, we've got a single work instruction and we're all doing things the same way,” says Leon Dunn, chief medical physicist at GenesisCare in Victoria.

“While the individual states operate as individual business units, the physics team operates as one, and the planners operate as one team as well,” adds Peter Mc Loone, GenesisCare’s head of physics for Australia. “We are like one team nationally, so we try to do things the same way. Obviously, it makes sense to make sure everyone's checking the plans in the same way as well.”

User approved

GenesisCare implemented RadCalc more than 10 years ago, selected in part due to the platform’s impressive reputation amongst its users in Australia. “At that time, RadCalc was well established in radiotherapy and widely used,” explains Dunn. “It didn't have all the features that it has now, but its basic features met the requirements we needed and it had a pretty solid user base.”

Today, GenesisCare’s physicists employ RadCalc for plan verification of all types of treatment across a wide range of radiotherapy platforms – including Varian and Elekta linacs, Gamma Knife and the Unity MR-linac, as well as superficial treatments and high dose-rate brachytherapy. They also use RadCalc’s plan comparison tool to check that the output from the treatment planning system matches what was imported to the MOSAIQ electronic medical record system.

“Before we had the plan comparison feature, our radiation therapists had to manually check control points in the plan against what was on the machine,” says Mc Loone. “RadCalc checks a wide range of values within the plan. It's a very quick check that has saved us a lot of time, but also increased the safety aspect. We have certainly picked up errors through its use.”

Keeping treatments safe

The new feature that’s helping to make a big difference, however, is GenesisCare’s recent implementation of RadCalc’s 3D independent recalculation tool. Dunn explains that RadCalc previously performed a 2D comparison between the dose to a single point in the treatment planning system and the calculated dose to that point.

The new module, on the other hand, employs RadCalc’s collapsed-cone convolution algorithm to reconstruct 3D dose on the patient’s entire CT data set. Enabled by the introduction of graphics processing units, the algorithm performs a completely independent 3D recalculation of the treatment plan on the patient's data. “We've gone from a single point to tens of thousands of points,” notes Dunn.

Importantly, this 3D recalculation can discover any errors within a treatment plan before it gets to the point at which it needs to be measured. “Our priority is for every patient to have that second check done, thereby catching anything that is wrong with the treatment plan, hopefully before it is seen by the doctor. So we can fix things before they could become an issue,” Dunn says, pointing out that in the first couple of months of using this tool, it highlighted potentially suboptimal treatment plans to be improved.

In contrast, previous measurement-based checks had to be performed at the end of the entire planning process, after everyone had approved the plan and it had been exported to the treatment system. “Finding an error at that point puts a lot of pressure on the team to redo the plan and have everything reapproved,” Mc Loone explains. “By removing that stress and allowing checks to happen earlier in the piece, it makes the overall process safer and more efficient.”

Dunn notes that if the second check shows a problem with the plan, the plan can still be sent for measurements if needed, to confirm the RadCalc findings.

Increasing efficiency

As well as improving safety, the ability to detect errors early on in the planning process speeds up the entire treatment pathway. Operational efficiency is additionally helped by RadCalc’s high level of automation.

Once a treatment plan is created, the planning staff need to export it to RadCalc, with a single click. RadCalc then takes care of everything else, importing the entire data set, sending it to the server for recalculation and then presenting the results. “We don't have to touch any of the processes until we get the quality checklist out, and that's a real game changer for us,” says Dunn.

“We have one RadCalc system, that can handle five different states and several different treatment planning systems [Varian’s Eclipse and Elekta’s Monaco and GammaPlan],” notes Mc Loone. “We can have 130 different plans coming in, and RadCalc will filter them correctly and apply the right beam models using that automation that LAP has built in.”

Because RadCalc performs 100% software-based checks, it doesn’t require access to the treatment machine to run the QA (which usually means waiting until the day’s clinical session has finished). “We're no longer waiting around to perform measurements on the treatment machine,” Dunn explains. “It's all happening while the patients are being treated during the normal course of the day. That automation process is an important time saver for us.”

This shift from measurement- to software-based QA also has a huge impact on the radiation therapists. As they were already using the machines to treat patients, the therapists were tasked with delivering most of the QA cases – at the end of the day or in between treatment sessions – and informing the physicists of any failures.

“Since we've introduced RadCalc, they essentially get all that time back and can focus on doing what they do best, treating patients and making sure it's all done safely,” says Dunn. “Taking that burden away from them is a great additional bonus.”

Looking to the future, GenesisCare next plans to implement RadCalc’s log file analysis feature, which will enable the team to monitor and verify the performance of the radiotherapy machines. Essentially, the log files generated after each treatment are brought back into RadCalc, which then verifies that what the machine delivered matched the original treatment plan.

“Because we have so many plans going through, delivered by many different accelerators, we can start to build a picture of machine performance,” says Dunn. “In the future, I personally want to look at the data that we collect through RadCalc. Because everything's coming through that one system, we've got a real opportunity to examine safety and quality at a system level, from treatment planning system through to patient treatment.”