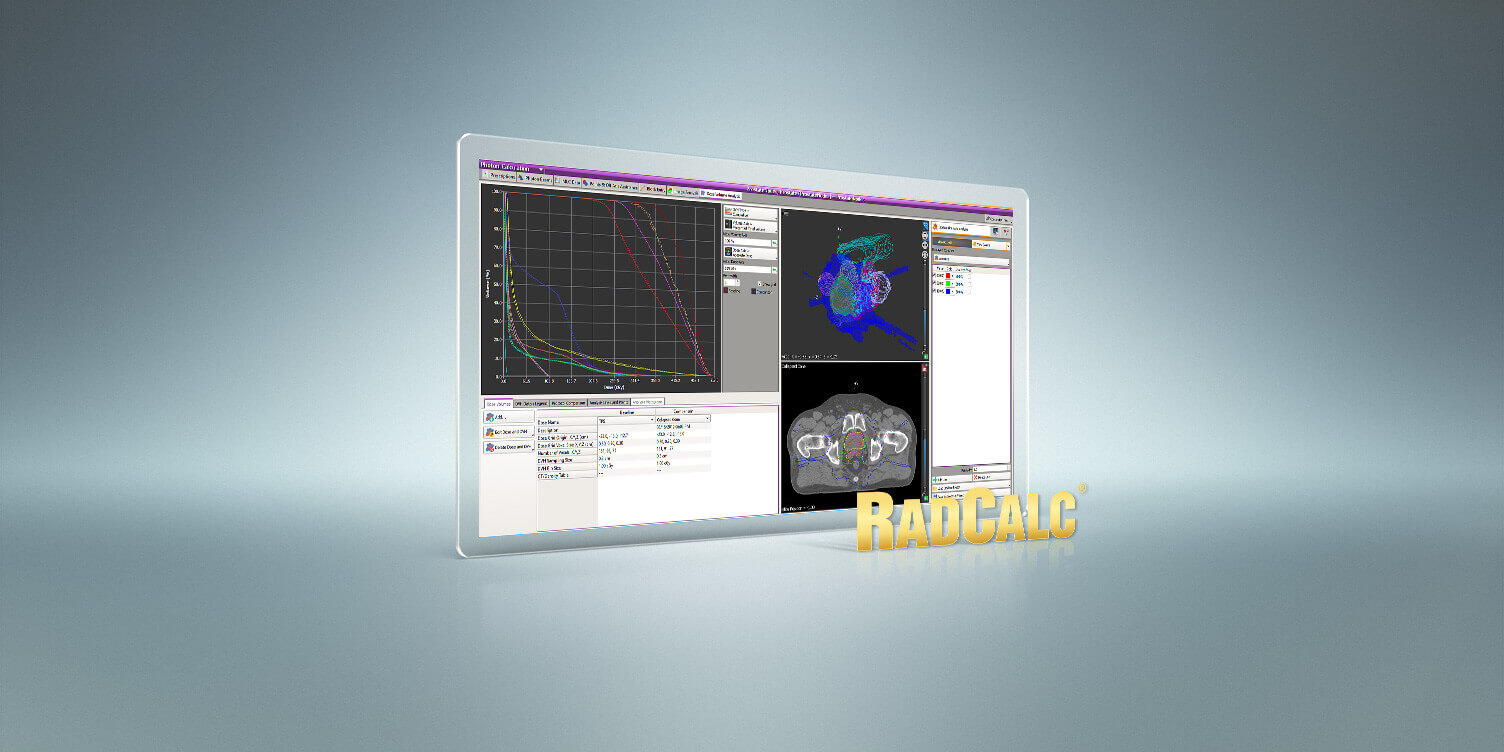

RadCalc innovations reinforce the benefits of independent QA

LAP is majoring on functional and commercial innovation with the roll-out of automated 3D dose verification for its RadCalc QA software

While the coronavirus pandemic wreaks havoc across national healthcare systems and the global economy, many technology companies have bunkered down and spent a good chunk of 2020 focusing on what they do best: relentless product innovation. A case study in this regard is the development team behind RadCalc QA secondary check software, a suite of widely deployed quality-assurance (QA) tools that provides medical physicists and dosimetrists with fully automated and independent dosimetric verification of their radiotherapy treatment planning systems (TPS).

Among a raft of advanced RadCalc features unveiled this year, top billing goes to the addition of automated 3D dose-volume verification – a result of the successful integration of Monte Carlo and collapsed-cone dose calculation algorithms into the platform. That 3D capability is reinforced by a continuous-improvement mindset – aligned with the evolving operational priorities of end-users at more than 2500 clinics worldwide – which ensures that automation, speed and workflow efficiency remain hard-wired into the RadCalc develop-and-release programme.

3D thinking

“For the past 20 years, we have provided independent QA software that’s fast, easy-to-use and accurate when it comes to identifying TPS dose errors,” explains Jim Dube, president and co-founder of the RadCalc software portfolio, part of LAP’s growing QA product line in radiotherapy. As such, the addition of automated 3D dose verification represents a natural progression for RadCalc, ensuring enhanced QA accuracy for harder-to-treat cases – for example, metastatic brain tumours or small tumour targets surrounded by lung heterogeneities – as well as an independent check for a range of advanced treatment modalities, including intensity-modulated radiation therapy (IMRT), volumetric modulated-arc therapy (VMAT), stereotactic radiosurgery (SRS), stereotactic body radiotherapy (SBRT) plus hypofractionation and ultrahypofractionation.

“Independent verification is, and will remain, a big deal for medical physicists and for the radiotherapy equipment vendors.”

Under the hood, RadCalc’s 3D Monte Carlo module exploits the well-established BEAMnrc dose engine in tandem with proprietary machine modelling acquired from the medical physics team at McGill University, Canada. The collapsed-cone convolution superposition algorithm is the result of a separate acquisition covering the source code and related patents of a product called DosimetryCheck (purchased from US radiological software specialist Math Resolutions back in 2017). “Our investment in Monte Carlo and collapsed-cone algorithms gives users a higher degree of certainty in their QA 3D dose calculations,” adds Dube. “That certainty translates into improved targeting accuracy and dose distribution accuracy – and ultimately better patient outcomes.”

If accuracy is a given for 3D dose verification, so too are automation and speed. Put simply, says Dube, all the physicist has to do is export a treatment plan via their DICOM RT and RadCalc will automatically verify the plan using either a Monte Carlo or collapsed-cone algorithm, generating results in minutes. “If the treatment plan doesn’t pass versus preset criteria,” he adds, “RadCalc will prompt the user to investigate what’s going on using a suite of dose analysis tools. They can slice-and-dice the plan just about any way they want to see where the hot or cold spot is and figure out what to do from there.”

Listening to the user

Right now, the RadCalc team is hard at work fleshing out the development roadmap for 2021 and beyond, including the release of 3D EPID-based functionality to underpin true measurement-based IMRT QA and in vivo verification. In short, RadCalc will import the necessary EPID data/image files, process them, and then send to the collapsed-cone dose engine to calculate the dose.

Operationally, RadCalc’s incorporation into the LAP group (in January 2019) has also opened up new growth opportunities through the latter’s global customer base. LAP laser systems are used worldwide for patient positioning in radiotherapy, both in the imaging and treatment unit. More broadly, the company is focused on delivering the enabling technologies for next-generation radiation therapy with ongoing innovation across its QA and multileaf-collimator product lines.

Capitalizing on that access, Dube concludes, starts and ends with RadCalc’s core value proposition to the radiation oncology community: “Independent verification is, and will remain, a big deal for medical physicists and for the radiotherapy equipment vendors. Why wouldn’t they want independent QA providing a double-check of their treatment plans?”

Find the original article on the Physics World website.