Laser projection increases efficiency in composite manufacturing

COTESA uses LAP CAD-PRO laser projectors to accelerate lay-up processes during composite production of GFRP fuselage components

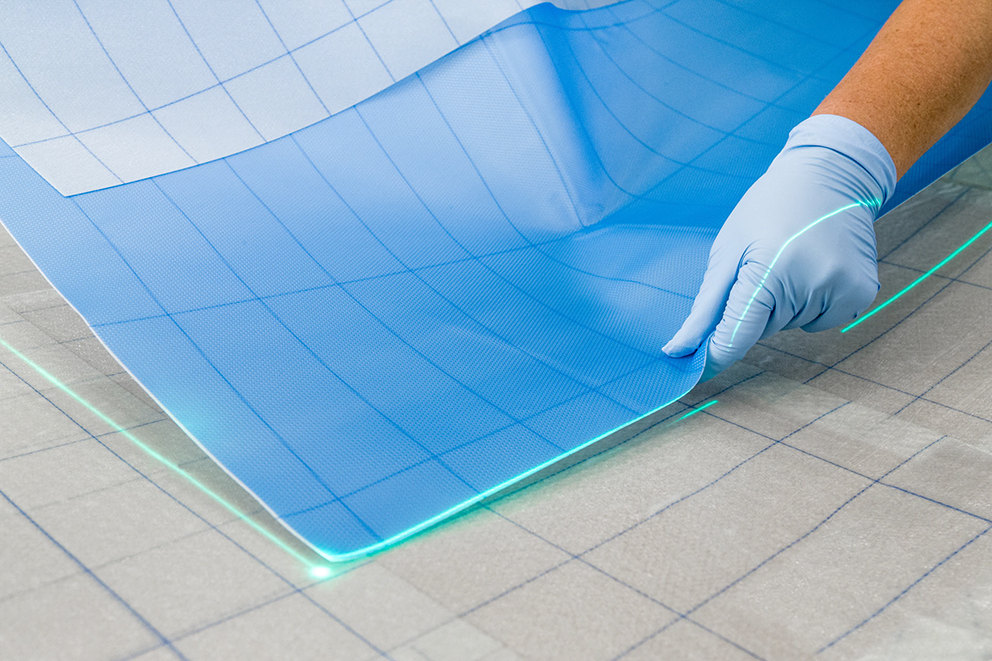

COTESA, a leading manufacturer of high-quality composite fiber components for the aviation industry, manufactures GFRP fuselage components at its Mochau factory in Germany. Thanks to the laser positioning system, manual measuring, physical templates and layer schemes are now a thing of the past.

The facility was expanded to around 40,000 square feet in order to accommodate a contract that saw the increase of the vertical range of manufacture at COTESA to include painting and assembling components. The factory delivers 25,000 fiber-glass reinforced plastic (GFRP) fuselage parts for the A320 family to Airbus, in Hamburg, every year. More than 30 different fuselage components will eventually now be produced in series. This also includes considerably larger, more complex components. To ensure even more effective production practices in future, COTESA has implemented LAP’s laser projection system, including CAD-PRO laser projectors and the PRO-SOFT control software, at all laminating workstations.

Download the PDF version of the application report and read the full story.

Images: ©Eric Shambroom Photography